Place |

Name |

Characteristic in the rating |

| 1 | Expanded clay | The most environmentally friendly |

| 2 | Basalt wool | The best resistance to deformation. Long service life |

| 3 | glass wool | Popular insulation for frame structures |

| Show more | ||

| 1 | Foamed polyethylene on a foil base | The thinnest insulation. High layer efficiency |

| 2 | polyurethane foam | Monolithic coating |

| 3 | Expanded polystyrene (styrofoam) | most popular heater |

| Show more | ||

| 1 | Chipboard | The most common floor insulation |

| 2 | Sawdust | Best price |

| 3 | Cellulose wool (ecowool) | The most environmentally friendly material. Provides microclimatic balance |

| Show more | ||

Read also:

To improve comfort and reduce heat loss in heated living spaces, one of the most effective means is floor insulation. Depending on its device (wooden or concrete screed), various types of insulation can be used.These works can be carried out not only in private houses - in multi-apartment residential buildings, a warm floor on the ground floor is a rarity, and cutting off a cold basement with an effective insulator is often the only solution to the problem.

Our review presents the best types of insulation available on the domestic building materials market. When compiling the rating, the operational properties of the material, the opinions of professional builders, as well as the positive experience of the owners who insulated their homes in one of the presented ways were taken into account.

The best mineral floor insulation

5 slag wool

Average price: 330 rub. (0.24 m³)

Rating (2022): 4.2

The most budgetary material for warming wooden floors, both in non-residential premises and in a private house, is one of the varieties of mineral heaters - slag wool. Despite the fact that this insulation is not the most popular among those on the market, it has a number of advantages: low price, resistance to fire, the highest thermal conductivity in the class, ease of use, etc. Floor insulation using slag wool is rarely used for subsequent pouring of concrete screeds. After cutting off the material with waterproofing, which is very important, given the ability of the insulation to absorb moisture, the wood flooring is directly laid.

Since the main raw material for the manufacture of slag wool is the waste of the metallurgical industry, one should be more careful in choosing a manufacturer - the absence of harmful impurities in the composition is the main selection criterion.You should also use basic safety equipment during the installation of slag insulation. It is enough to use construction goggles and a regular respirator to protect the respiratory tract and eyes from the microfibers of this material.

4 Foam glass

Average price: 4310 rub. (0.5 m³)

Rating (2022): 4.5

Foam glass insulation, which appeared back in the 30s of the last century, is still widely used today in the performance of repair and construction work related to the preservation of heat indoors. The basis of this insulation is silicate glass mixed with a gas-forming material, which, under the influence of high temperatures, foams the mass and significantly increases it in size. On the market, foam glass is presented in a wide variety of forms, in the form of crushed stone, sand, granules, blocks or plates. For floor insulation, granulated foam glass is more popular.

The material has the longest service life, which is more than a hundred years. This insulation is not subject to combustion, moisture absorption, exposure to microorganisms, etc. When carrying out work on insulation using foam glass, a large percentage of shrinkage should be taken into account, reaching in some cases 25-30%. This insulation can be used both under a concrete screed and under any floor covering. If the height of the room allows, insulation can be carried out using foam glass blocks, the use of which is more effective when cutting off the floor of the first floor from the basement. The only drawback of this material is the high cost.

3 glass wool

Average price: 1100 rub. (0.75 m³)

Rating (2022): 4.7

One of the main conditions for a comfortable stay in a wooden tom is a warm floor. For its thermal insulation, a long-known insulation on the building materials market is used - glass wool. It is a mixture of glass waste, dolomite and limestone, which provides the material with a low cost. It is successfully used not only for insulating floors on logs, but also for attics, roofs, ceilings, water pipes, etc. The only thing to consider when insulating a house with this material is the high ability of glass wool to absorb moisture. To preserve its best thermal insulation properties, high-quality hydro- and vapor barrier of the layer should be provided.

With one of the lowest thermal conductivity values, glass wool prevents heat loss, which is the main condition for ensuring a comfortable indoor temperature. Also, this material has a high class of fire safety, as it is resistant to fire. Glass wool demonstrates better resistance to deformation, due to its high elasticity, this insulation takes its original shape after any mechanical impact. The only drawback is that it is not advisable to use it for warming the floors of the first floors under a screed.

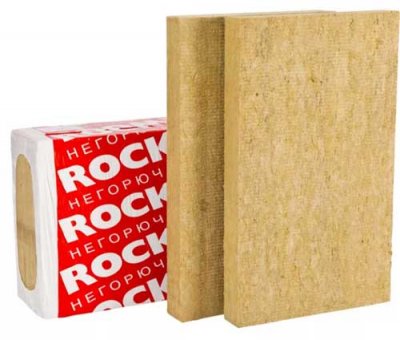

2 Basalt wool

Average price: 450 rub. (0.288 m³)

Rating (2022): 5.0

Probably, one of the most popular materials for insulation, roofs, facades and floors on the first floors of apartment buildings is basalt wool. This insulation is obtained by blowing molten volcanic rock (basalt), forming the resulting fibrous mass into rolls or mats.The composition, which is distinguished by its special strength, is not subject to deformation, due to which it retains its original shape throughout its entire service life, which, judging by the assurances of the manufacturers, is at least 50 years. Due to the fact that this insulation has a light weight, it does not carry any load on the foundation, while providing excellent thermal insulation and absorption of acoustic waves.

When insulating the floor with a heating function, this insulation will be the best choice, as it has the highest resistance to critical temperatures, withstanding up to 1500 ° C. At the same time, this material is absolutely safe for humans, and a slight release of phenol is possible only under conditions of heating up to 700 ° C, which is basically impossible under normal conditions. Basalt insulation is not damaged by pests and fungi, has the best water-repellent properties and is easy to install.

1 Expanded clay

Average price: 120 rub. (0.035 m³)

Rating (2022): 5.0

Since the best thermal insulation properties of clay have been known for a very long time, respectively, building material based on this natural component is well-deservedly popular when it comes to home insulation. An environmentally friendly composition, completely free of harmful impurities, is formed in the form of porous, almost weightless granules. The use of this insulation is economically justified if it is necessary to raise the floor, when it is required to fill in a level of screed that is decent in height. Expanded clay in this case minimizes the consumption of concrete mix. Also, this lightweight material will be the best choice for floor insulation in old houses where wooden floors are not able to withstand heavy loads.

An additional advantage of the presented insulation is the best moisture and frost resistance. Also expanded clay is not subject to corrosion and mold, due to which it has the longest service life and is not prone to destruction. The screed made using this insulation guarantees not only a warm floor, but also normalizes the microclimate inside the room.

The best polymer floor insulation

5 Polyvinyl chloride (viniplast)

Average price: 112 rub. (0.56 m²)

Rating (2022): 4.4

A small thickness makes this material one of the most popular for isolating the first floors of apartment buildings from a cold basement. It has high rigidity, is resistant to ultraviolet and high temperatures, and is completely immune to moisture. When insulating the floor under a concrete screed, sheets with a thickness of 1 to 4 cm can be used, which are best glued together using polyvinyl chloride-based compositions. This installation method will provide the most effective protection against moisture and prevent heat leakage.

At the same time, this material does not burn at all (at 200 ° C it chars and decomposes), and its thermal conductivity coefficient is only 0.00044 W / m * K, which allows us to consider this material one of the most effective for arranging a warm floor. Viniplast, moreover, is quite compact and does not lead to a significant decrease in the internal volume of the premises.

4 Penoizol-liquid foam

Average price: 925 rub. (0.5 m³)

Rating (2022): 4.5

This insulation is a type of urea foam and has a number of characteristics that determine its advantage over more expensive insulating material. For reasons to use it under a concrete screed will not work. The purpose of the material is to fill the voids of frame structures, and penoizol seems to be the most profitable solution for insulating a wooden floor.

It is not attractive to rodents, is not flammable, and without access to sunlight and air is capable of long-term operation, the period of which is measured in tens of years (the warranty period for insulation is 30 years). It is also possible to use ready-made sheet foam insulation - in this case, the weak point of the insulation will be the seams, which will have to be blown out with mounting foam to minimize heat loss.

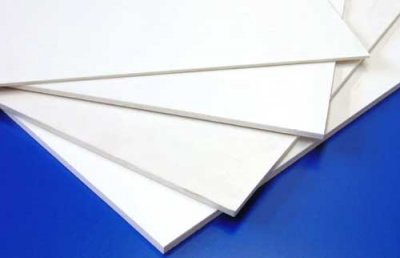

3 Expanded polystyrene (styrofoam)

Average price: 310 rub. (0.2 m³)

Rating (2022): 4.7

When the question arises of floor insulation in a private house or apartment on the ground floor, many prefer such affordable and easy-to-install material as polystyrene foam. The process of creating this insulation is very simple and consists in the solidification of air-filled cells obtained by foaming polystyrene. On the market, this thermal insulation material is presented in a variety of forms and types: from crumbly granules to the most familiar foam boards, which differ in size and density. For insulation of a house or floor under a screed, extruded polystyrene foam will be the best choice. Although it has a higher price, it also has increased strength and improved insulating characteristics.

The main advantage of the presented insulation is one of the lowest thermal conductivity coefficients, which is even lower than mineral wool and can reach 0.028 - 0.03 W / m * K. This confirms the best thermal insulation properties of expanded polystyrene. Since this material is subject to negative environmental influences, it must be protected from mechanical and ultraviolet effects. In the case of floor insulation, this role is played by a concrete screed, which also minimizes the risks of fire and the release of harmful gases.

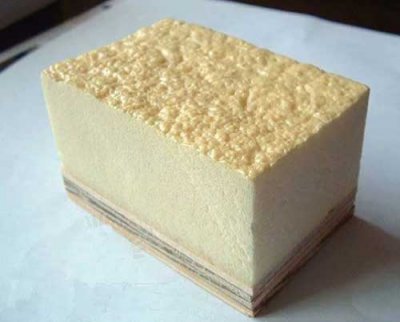

2 polyurethane foam

Average price: 496 rub. (0.9 l)

Rating (2022): 5.0

The modern high-tech method of insulating houses with the help of polyurethane foam is gaining more and more popularity. This insulation is absolutely not subject to the damaging effects of the ultraviolet spectrum, moisture and any natural phenomena. Thermal insulation of the floor with this material, which is based on polyurethanes enriched with inert gases, is the most highly effective. The filling of voids is carried out by special equipment by spraying, which allows you to adjust the required layer thickness. One of the main advantages of this method of insulation is the absence of joints and seams, which guarantees better tightness.

Due to the fact that polyurethane foam has the lowest thermal conductivity, a layer of 100 mm is sufficient for maximum heat retention in the room. Considering the best indicators of environmental friendliness and high service life (up to 60 years), the choice in favor of this floor insulation is obvious.An additional advantage of this material is the speed of work - it will take one day for specialists to insulate an area of 200-300 m².

1 Foamed polyethylene on a foil base

Average price: 800 rub. (18 m²)

Rating (2022): 5.0

Polyethylene foam is a thin cellular material obtained on the basis of numerous experiments with polymers, which has the best characteristics of a thermal insulation material, reinforced many times with aluminum foil. This insulation is the most popular when choosing a material for underfloor heating on the ground floor. It will cut off the cold rising from the basement, and thanks to its reflective properties, it will not allow heat loss from the room. At the same time, the laying of this insulation under the screed will practically not affect the height of the room, since its thickness is in the range of 3-10 mm.

This modern material demonstrates excellent water-repellent properties and better resistance to any temperature fluctuations, due to which some types of this insulation are used in the construction of gas stations, saunas and other facilities. The noise-absorbing properties of foamed polyethylene and safety parameters also speak in favor of choosing this insulation. It is non-flammable and does not emit harmful substances at all. Since the decomposition period of polyethylene reaches 200 years, this material has the longest service life.

The best wood chip floor insulation

5 Plywood

Average price: 1350 rub. (2.977 m², sheet thickness 18 mm)

Rating (2022): 4.4

This multilayer material can be used, among other things, for floor insulation. Sufficiently strong sheet plywood is laid on a concrete screed or on top of a wooden deck. In the latter case, its use is greatly simplified - just tighten the sheet with self-tapping screws. It can also be used to insulate the first floors, however, before laying on concrete, it is better to carry out a preliminary waterproofing of the base.

A significant disadvantage of this material for providing underfloor heating is its high susceptibility to moisture and low resistance to fire. The latter indicator is much higher than ordinary wood, so it practically does not affect the choice. Nevertheless, this material is easy to work with, and it is often used as a heater, since plywood has a good thermal conductivity. Its level is, on average, from 0.110 to 0.175 W / m * K, depending on the raw materials used and humidity.

4 OSB

Average price: 600 rub. (3.125 m², sheet thickness 12 mm)

Rating (2022): 4.5

This sheet material is perfect for insulation. It can be applied both on a concrete screed and on an old wooden floor. In addition, it perfectly levels the surface and makes it completely ready for covering with linoleum or other floor covering. Sheet thickness can vary from 0.9 to 2.2 cm, which allows you to choose the most optimal layer in terms of price and characteristics.

The use of OSB-plates for arranging a warm floor, especially on the first floors of apartment buildings, is one of the most practical - the layer is laid without dismantling the screed, which greatly reduces the cost of work. At the same time, the material is environmentally friendly, can be painted, resistant to moisture.The thermal conductivity of the insulation depends on its thickness and is fully comparable with wooden structures.

3 Cellulose wool (ecowool)

Average price: 579 rub. (15 kg)

Rating (2022): 4.7

Cellulose insulation, which is based on recycled materials, is environmentally friendly, and one of the most effective among modern thermal insulation materials. Due to its unique structure, better performance and availability, ecowool is gaining more and more popularity among the heaters on the market. Although the work of spraying cellulose wadding must be carried out by a specialist using a blow gun, these costs are offset by the presence of the highest quality and most reliable insulating layer.

The thermal conductivity of this insulation is 0.037-0.042 W / m * K, which guarantees maximum heat retention in a room where the floor is insulated with cellulose wool. The optimal balance of microclimatic indicators inside the premises provides the ability of ecowool to regulate moisture exchange. Among other things, this material demonstrates the best sound absorption up to 63 dB. Since the material is a non-flammable product, it can be safely used for thermal insulation of the floor even in a wooden house.

2 Sawdust

Average price: 81 rub. (20 l)

Rating (2022): 4.7

The use of sawdust in the arrangement of a private house is a long-known and time-tested method of insulating the floor and interfloor ceilings. The effectiveness of this method largely depends on the type of wood and the selected fraction of wood waste.For better thermal insulation, experts recommend using a mixture of chips and dust, due to which all voids will be filled as tightly as possible and the percentage of shrinkage will be minimized. You should be very careful in choosing this material, since impurities, insufficient drying or poor-quality raw materials are unacceptable.

Floor insulation using sawdust can be carried out in various ways, one of which involves filling dry sawdust, followed by a wooden floor. It is also possible to carry out high-quality thermal insulation of the floor by pouring a concrete screed with the direct addition of chips to it. Today, the market offers a variety of types of insulation, which are based on sawdust, but at the same time they have improved characteristics and are easy to use, as well as less negative impact of various factors. The most common derivatives are wood pellets with the addition of an antiseptic or concrete sawdust blocks.

1 Chipboard

Average price: 225 rub. (1.0 m²)

Rating (2022): 4.8

Compressed sawdust, produced in the form of boards, is widely used in repair and construction work. Laying chipboard on top of a concrete screed or wooden floor performs two functions at once - it levels the surface and provides thermal insulation. This insulation has the highest rate of strength and biological stability. At the same time, chipboard is considered a combustible material and belongs to the 4th class of fire safety, like wood. When performing work on the thermal insulation of a house using this insulation, one should take into account its susceptibility to destruction under the influence of moisture.

Despite the fact that this material is relatively safe for humans, some features should be taken into account when choosing it. Thus, the insulation board from class E 0.5 has the lowest indicator for the content of harmful substances, and sheets from class E 2 are not recommended for indoor use. The ease of installation work using chipboard, combined with the invariance of forms under the influence of various factors, as well as the affordable price, largely determine the choice in favor of this floor insulation.